Silicon Carbide

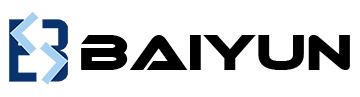

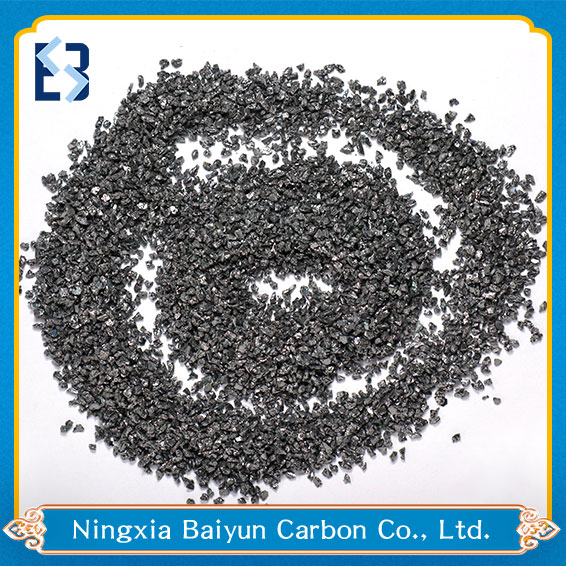

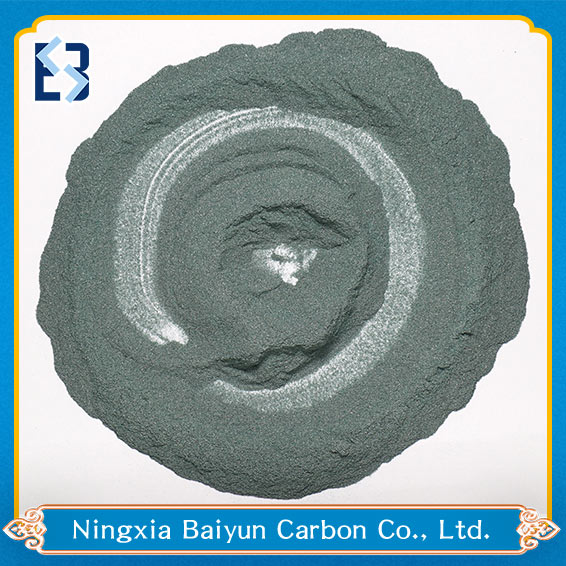

Silicon Carbide Black silicon carbide (SIC) is made from quartz sand and carbon( anthracite coal tar or petroleum coke) in electric esistance furnace at high temperature. It has the characteristic of high hardness excellent electrical and h

info@baiyuncarbon.com

Whatsapp+8618695245206

Product Details

Applications

Product Details

Black silicon carbide (SIC) is made from quartz sand and carbon( anthracite coal tar or petroleum coke) in electric esistance furnace at high temperature. It has the characteristic of high hardness, excellent electrical and heat conductivity, low thermal expansion, and high abrasion resistance. Thus, SIC is the most suitable material of abrasives, refractories, deoxidizer of metallurgical, special ceramics, electric heating elements and so on.

Silicon Carbide Applications:

1. Abrasives

A: bonded and coated abrasive tools such as

grinding wheels, whetstonewire saws, sanding belts abrasive paper etc.

B: surface treatment such as sandblastinggrinding

blasting,lapping and polishing

C:non-slip floor, wear-resistance floor, etc.

2.Metallurgical Deoxidizer

3. Refractories, such as refractory bricks,lining of

high furnace, etc.

4.Special Ceramics

5.Electric Heating Elements

6.Semi-conductors and Silicon Carbide Fibers(high-purity

single crystal SIC only).

Silicon Carbide description

Black silicon carbide (SIC) is made from quartz sand and carbon( anthracite coal tar or petroleum coke) in electric esistance furnace at high temperature. It has the characteristic of high hardness, excellent electrical and heat conductivity, low thermal expansion, and high abrasion resistance. Thus, SIC is the most suitable material of abrasives, refractories, deoxidizer of metallurgical, special ceramics, electric heating elements and so on.

|

Grade |

Chemical Content | ||

| SIC% | F.C% | Fe2O3% | |

| DMS98 | 98.00 | 0.20 | 0.40 |

| DMS97 | 97.00 | 0.35 | 0.60 |

| DMS96 | 96.00 | 0.40 | 0.60 |

| DMS95 | 95.00 | 0.50 | 0.70 |

| DMS92 | 92.00 | 1.50 | 1.40 |

| DMS90 | 90.00 | 2.00 | 1.60 |

| DMS88 | 88.00 | 2.50 | 1.80 |

| DMS85 | 85.00 | 3.00 | 2.00 |

| Size |

1-3,3-5,5-8,0-10,1-10mm 16,20,24,30,36, 46,60,80,100,120,150,180,200, 320mesh, Customized |

||

Silicon Carbide Applications:

1. Abrasives

A: bonded and coated abrasive tools such as

grinding wheels, whetstonewire saws, sanding belts abrasive paper etc.

B: surface treatment such as sandblastinggrinding

blasting,lapping and polishing

C:non-slip floor, wear-resistance floor, etc.

2.Metallurgical Deoxidizer

3. Refractories, such as refractory bricks,lining of

high furnace, etc.

4.Special Ceramics

5.Electric Heating Elements

6.Semi-conductors and Silicon Carbide Fibers(high-purity

single crystal SIC only).

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.